-

- Release on2024-01-02

- Kraft paper is a robust paper that, due to the manufacturing process, is much stronger than regular paper. This process often uses woodchips and other wood waste to create the paper, which are steamed and pulped before being spread to dry for cutting, With Zipper Design Window Printing Composite , transport and assembly into a variety of eco-friendly alternative to single-use plastic. Not only is the end product 100% recyclable, but manufacturing plants are also equipped to reuse water and chemicals wherever possible which makes the whole process far more eco-friendly than those of single-use plastics.Our fatory has Free Customization Of Samples servise,and has more than 20 years in this career。Kraft paper does not get bleached. Bleaching is what causes paper to lose strength, so the absence of bleaching is what makes kraft paper biodegradable, recyclable, and compostable, while also remaining strong enough to be used for bags. The lack of bleaching also allows the kraft paper material to speak for itself, with a rough, authentic finish that looks and feels beautiful. As an eco-friendly solution, the manufacture and use of kraft paper bags has a significantly smaller impact on the environment than plastics. The process is well-curated to produce an eco-friendly material without contributing significantly to environmental pollution, and now this material is widely accessible, it’s easier than ever for individuals and businesses of all sizes to ditch the single-use plastics....Read More>>

-

- Release on2024-01-02

- With the development of science and technology, these problems have been solved, and if necessary, the food can be prevented from spoiling on the way, and the flavor of the food will not be damaged. With Zipper Waterproof Vacuum packaging has a good effect of preventing the entry of air, resisting external pressure, and Printing Logo Hanging Holemaintaining the freshness of food. When visiting relatives and friends, always keep aluminum foil bags at home for packaging, which is more face-saving. However, some things are ready-to-eat, and they will easily deteriorate when they are carried. Therefore, there are many things that are very delicious, but they cannot be taken away. Mildew and deterioration may also be caused by the loss of the original taste of the food due to too long time. The aluminum foil bag is a bag made of a variety of plastic films after compounding and then passing through a bag-making machine. It is used to package food, pharmaceutical industrial products, and daily necessities. Such products are suitable for moisture-proof, light-proof, and vacuum packaging of large-scale precision machinery and equipment, chemical raw materials, and pharmaceutical intermediates. The four-layer structure is mostly used, which has good water and oxygen barrier functions. The products must be tested by GB and ASTM standards, and the products meet the requirements of environmental protection (third-party test reports can be provided)....Read More>>

-

- Release on2023-12-28

- Pet owners spent more on dog and cat food and treats in 2020 versus 2018, according to the APPA National Pet Owners Survey, and more owners bought online....Read More>>

-

- Release on2023-12-28

- The mass of aluminum foil varies with the amount of it. The approximate density of aluminum foil is 2.7 grams per centimeter; therefore, 1 centimeter of it has a mass of 2.7 grams. It ranges in thickness from 0.07 to 25 micrometers....Read More>>

-

- Release on2023-12-28

- Kraft paper bag packaging is very common in our daily lives, such as file bags, nut bags, coffee bags, etc. In recent years, with the strengthening of people’s environmental awareness, products packaged with kraft paper materials are increasingly favored by consumers....Read More>>

-

- Release on2023-12-28

- Let's set the stage: It's the year 850, and legend has it that an Ethiopian herdsman named Kaldi observed his goat acting especially chipper after eating red berries from a nearby bush. After consuming the berries himself and experiencing feelings of energy and elation, he ran to the nearest monastery to tell of their amazing effect. The chief monk, thinking Kaldi was possessed, burned the berries in a fire, calling them evil. But later, a rebellious young monk fished the berries from the remains of the fire and mixed them with water for a drink, effectively making himself the first barista. Thus, coffee was born....Read More>>

-

- Release on2023-12-28

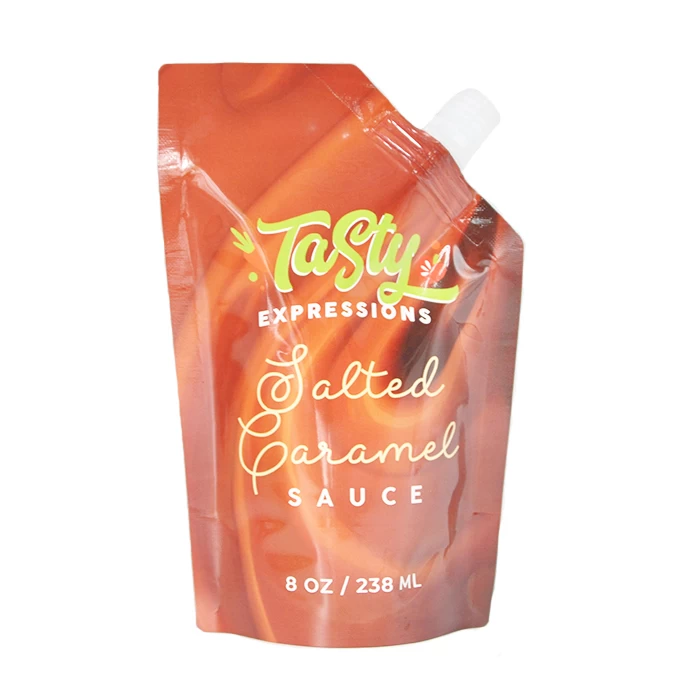

- In the realm of packaging solutions, the Spout Pouch has emerged as a versatile and innovative option that has transformed the way products are stored, transported, and consumed. Combining functionality with aesthetic appeal, the spout pouch has become a go-to choice for a variety of industries, from food and beverages to personal care and beyond. As an expert in packaging solutions, I am pleased to provide a comprehensive overview of the spout pouch, its evolution, and the manifold advantages it offers....Read More>>

-

- Release on2023-12-28

- The need to contain, store, and transport materials has been around since the early days of humanity. However, overtime, packaging has transformed from simply fulfilling a need to becoming integral to a brand’s messaging as well as consumer experience....Read More>>

-

- Release on2023-12-25

- Layfield Flexible Packaging, a Canadian company that makes standup plastic pouches at its factory in Richmond, B.C., mainly sells its products for medical uses, such as blood bags, as well as for food and consumer packaging. According to company president Mark Rose, there are good reasons — including environmental ones — why pouches have come to replace so many aluminum cans, glass jars, and hard plastic containers. For one thing, they're lighter and use less material, saving energy and costs on manufacturing and transportation.The story of the standup pouch, as it's called, shows how innovation in packaging can sometimes come with some big environmental challenges. But as the industry grows — the global standup pouch market was worth $22.74 billion US in 2016 and is expected to nearly double to $40.65 billion in 2022, according to the marketing firm Stratistics MRC — there are people working on solutions.The result is a convenient, resealable package that keeps food fresh, reducing food waste that can itself cause greenhouse gas emissions, Rose said. And the packaging is appealing and rigid enough to stand up on a shelf — helping to market the product. The downside? Because it's made of layers of different materials, it's not recyclable. "You're not going to pull apart that glue at any recycling facility," Rose said. Nor is melting it down going to help, since the different plastics have completely different melting temperatures.Small quantities of some specific standup pouches are currently being recycled: They're collected through manufacturer-funded programs and turned into plastic lumber through a company called TerraCycle. But what should be done with the rest is a growing challenge, given the popularity of the pouches.While Rose is convinced that plastic pouches are still more environmentally friendly than other kinds of packaging, he has spent years trying to develop versions that are greener to dispose — partly at the request of customers. "Even though a plastic pouch is the most sustainable option we have currently available, people still seem to want more," he said. This spring, his company launched two kinds of recyclable pouches: Each contains only one kind of plastic — either polyethylene or polypropylene....Read More>>

-

-

Factory Customized Size Supports Printing Of Food Grade Heat Sealed Zippered Plastic Bags For SnacksRelease on2023-12-20

- Regulatory agencies that monitor food and beverage production require the use of food-grade materials at any point that the material may contact food. Packaging is no exception to these rules, leading to the development of food-safe plastics for use in packaging consumable products. Food-grade plastics follow stringent, government-monitored manufacturing processes to ensure they are safe for food contact. Numerous plastics are approved for food contact, leading to their use as food packaging. This article will discuss the types of food-grade plastics used in the packaging sector. PET is relatively ubiquitous, used in soft drink and single-use water bottles, as well as food-grade containers, bakery trays, snack packs, produce containers, and more. PET resin won’t degrade upon food contact, which makes it a popular choice for food packaging. Some of the other beneficial properties of PET include lightweight, high impact resistance, and corrosion resistance.CPET has undergone a process to make it more resistant to cracking when it experiences impacts at low temperatures, which is a common drawback of some standard PET plastic containers. CPET is more flexible and can withstand higher temperatures, making it appropriate for producing plastic food trays used with conventional oven, microwavable dinners, oven-proof plastic wrap, microwaveable storage containers, and more. CPET is also commonly used for ready-to-eat meals as well.Polypropylene is an ideal food-safe plastic for production processes that require high heat. It can be found in products ranging from prescription bottles to garden tools and automotive products. While fairly stiff, polypropylene is not as brittle as other common food packaging plastics. Food items that utilize polypropylene for packaging include yogurt, cream cheese/sour cream containers, ready-to-eat meals and VSP containers. Polypropylene has gained popularity for microwavable containers thanks to its high melting point....Read More>>

-

-

- Release on2023-12-20

- Stand-up pouches belong to the flexible packaging category and are also colloquially known as doypacks. They are primarily used as primary packaging for food, pet food and nutritional supplements. But stand-up pouches are also very suitable for non-food products such as clothing, cannabis or pharmaceutical products. There are a few things that go along with the planning, manufacturing and filling of Doypacks that you have to pay attention to. This guide will help you understand all the relevant topics to get to your dream package.Stand-up pouches can be produced in many different ways. There are different production techniques, especially regarding the bottom fold. A difference is made above all between a normal Doyen bottom and a so-called K-seal bottom. The two variants differ in the way the bottom fold of the pouch is integrated between the front and the back. The Doyen bottom has the disadvantage that a format-specific tool has to be ordered for it in each case. The K-seal bottom, on the other hand, has the advantage that any format can be produced with one and the same tool.We use both manufacturing variants in our production. We always produce our Doypacks in fixed formats with a Doyen bottom. Orders with a pouch in the desired format, we always produce with the K-seal bottom.A stand-up pouch can be made from a wide variety of materials. The most common material combinations are: Composite plastics such as PET/PE Kraft papers such as KRAFT/PET/PP Depending on the material, different properties result in terms of feel, print image, food compatibility and recycling. Especially pouches made of kraft paper are very popular, provide a very high-quality feel and always convey a sustainable image. In most cases, however, the material combinations of paper and plastic used are not officially recyclable (in Germany). In order to be able to recycle a stand-up pouch, the material used must be made of a so-called mono-material (e.g. PE/EVOH/PE). It is important that both the foil and components such as the zipper are made of one and the same material (PE foil + PE zipper). The most common mono materials are made of mono-PE and mono-PP. Plastic-free or industrially compostable stand-up pouches are also available, but these do not meet the same high requirements for the necessary barrier functions as, for example, an EVOH barrier does. The inner coatings of these pouches often consist of ultra-thin varnishes or organic coatings. These pouches usually also have significantly lower stability and durability. Our range includes a wide range of materials for stand-up pouches and flat pouches. Here you are guaranteed to find the right material for every requirement: Recyclable mono-plastics: PE/EVOH/PE in white (Full-PE) PE/EVOH/PE in transparent (Full-PE) Composite Plastics: PET/EVOH/PE in white PET/EVOH/PE in transparent metPET/EVOH/PE in silver metallic Kraft paper materials: Kraft paper brown / EVOH/PE Kraft paper white / EVOH/PE All our mono- and composite plastics are optionally available with a glossy or matt surface....Read More>>

-

- Release on2023-12-20

- The aluminum foil bag is a bag made of a variety of plastic films after compounding and then passing through a bag-making machine. It is used to package food, pharmaceutical industrial products, and daily necessities. Such products are suitable for moisture-proof, light-proof, and vacuum packaging of large-scale precision machinery and equipment, chemical raw materials, and pharmaceutical intermediates. The four-layer structure is mostly used, which has good water and oxygen barrier functions. The products must be tested by GB and ASTM standards, and the products meet the requirements of environmental protection (third-party test reports can be provided). Opaque, silver-white, reflective, with good barrier properties, heat-sealing properties, optical shading properties, high-temperature resistance, low-temperature resistance, oil resistance, fragrance retention; non-toxic and tasteless; softness, and other characteristics. PET/AL/PET/PE. Products with different composite materials and thicknesses can be customized as required. Storage environment temperature ≤ 38 ℃, humidity ≤ 90% 5. General product specifications: thickness 0.10mm and 0.14mm, three-side sealing, edge sealing 10mm, product specifications, and dimensions can be customized according to customer needs. (1) Suitable for all kinds of circuit boards, electronic products, precision machinery parts, consumer goods, industrial products, and another packaging. For example PC board, IC integrated circuit, electronic components, various LED industry SMT, lamp belt packaging, precision hardware, auto parts, and another packaging. (2) Food packaging: milk, rice, meat products, dried fish, aquatic products, preserved meat, roast duck, roast chicken, roast pig, quick-frozen food, ham, cured meat products, sausages, cooked meat products, pickles, bean paste, Preservation of fragrance, quality, taste, and color of seasonings....Read More>>