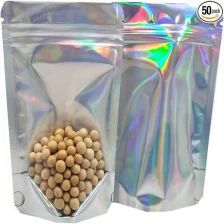

1. The aluminized film has excellent metallic luster and good reflectivity. Using it to package goods can beautify goods and improve the quality of goods.

2, aluminized film has excellent gas barrier, moisture barrier, light shielding and fragrance, not only for oxygen and water vapor has a strong barrier, but also can block almost all ultraviolet, visible light and infrared, can extend the shelf life and shelf life of the contents. Therefore, for food, medicine and other products that need to extend the shelf life, the use of aluminized film as a packaging is a very good choice, which can prevent food deterioration due to moisture absorption, oxygen permeability, light irradiation and other reasons. In addition, the aluminized film also has the property of keeping aroma, the aroma transmission rate is small, and the aroma of food can be kept for a long time. Therefore, aluminized film is an excellent barrier packaging material.

Aluminized film can also replace aluminum foil to a certain extent, and the amount of aluminum can be greatly reduced, which not only saves energy and materials, but also reduces the cost of commodity packaging.

4. The aluminized layer on the surface of the aluminized film has good conductivity and can eliminate the electrostatic effect. Therefore, the sealing performance is good, especially when packaging powdery items, it can ensure the sealing of the packaging, thereby greatly reducing the leakage. Incidence rate.

5. The shielding type can be partially aluminized to obtain any pattern or transparent window, and the contents can be seen.

6. It has good adaptability to post-processing such as printing and compounding.

7, the scope of application is very wide, currently mainly used in biscuits and other dry, puffed food packaging and some medicine, cosmetics packaging.

It is a packaging and storage product that combines practicality and aesthetics. Made of semi-transparent frosted material and featuring a durable zipper closure design, it is suitable for various scenarios.

More

The OPP ice cream transparent bags are made of food-grade biaxially oriented polypropylene (OPP) material, specially designed for frozen foods such as ice cream, popsicles, and ice cream bars. With high transparency, low-temperature resistance, moisture-proof and oil-proof properties, they ensure the freshness and hygiene of the products while enhancing the brand display effect.

More

Aluminum foil material has excellent sealing properties, effectively preventing tea from getting damp and oxidizing, maintaining the freshness and taste of the tea Aluminum foil bags are lightweight and easy to carry, commonly used packaging for many high-end tea brands.

More

The production of eight-sided sealed coffee bags first requires the selection of appropriate materials. Common materials include OPP, PE, CPP, PET, nylon, pure aluminum, and aluminum-coated materials, etc. The choice of these materials will affect the barrier performance, heat sealing performance, moisture-proof performance, and transparency of the packaging bag. For example, pure aluminum or aluminum-coated materials can provide good oxygen and light barrier properties, while nylon materials have high strength and toughness.

Eight-sided sealed coffee bags are usually printed to increase the product's attractiveness and brand recognition. The printing process includes electro-engraving copper plate high-speed printing, which can achieve high-definition pattern and text printing.

More

Vacuum bags, also known as nylon bags, are mainly made of NY/CPE or PET/NY/CPE. This product features excellent vacuuming effect, high transparency, low oxygen permeability, superior moisture-proof performance, high tensile strength and puncture resistance, as well as good heat-sealing and sealing properties. It is not prone to aging and is suitable for products such as hardware and electronic components that require vacuum packaging.

More

Aluminum foil zipper bags are a packaging solution that combines high barrier properties, sealing performance and convenience. They are made of multi-layer composite materials. The front is designed with a transparent window (usually made of PET or transparent PE), which can directly display the contents while retaining the light-blocking and moisture-proof characteristics of aluminum foil. They are widely used in the packaging needs of the food, pharmaceutical, electronic components, cosmetics and other industries.

More

The outer VMPET film of the aluminized Yin and Yang bag is a flexible packaging material formed by plating an extremely thin layer of metal aluminum on the surface of the plastic film with a special process. The inner layer is a heat-sealable CPE or CPP, which has anti-static, light insulation, oxygen insulation and other properties, and is the preferred alternative product of the aluminum foil bag

More

Made of high-quality food-grade thick plastic, tough and light, smooth edges, will not scratch you, and can be reused and easy to use.

More

Suction bag, is a new form of packaging, it combines the design of the self-supporting bag and the suction mouth, mainly composed of two parts of the suction mouth and the self-supporting bag portability: the suction mouth bag can be easily put into the backpack or even the pocket, and can be reduced with the reduction of the contents, more convenient to carry.

Sealing: With good sealing, can effectively avoid light and moisture, extend the shelf life of the product.

Exquisite printing: It has incomparable advantages in the printing performance of traditional beverage packaging, improving product grade and strengthening the visual effect of the shelf.

Versatility: can replace the bottle to use, save costs, improve the competitiveness of products in the market; With suction nozzle, galas chain, can be used repeatedly, strong sealing, easy to save, suitable for manual and automatic filling and sealing.

Coffee bag with air valve is a kind of bag designed for storing coffee beans, with one-way exhaust valve function, can effectively lock the freshness of coffee.

Product characteristics

one-way exhaust valve : This design makes the gas can only be discharged one-way, can not enter, so as to prevent the coffee beans from moisture and oxidation, maintain its freshness and aroma

eight-side seal design : The bag adopts the eight-side seal design, which is not only stable, but also can effectively isolate the air to ensure the best preservation of the coffee beans

moisture and anti-oxidation : The eight-sided sealing bag with air valve can effectively prevent moisture and oxidation and extend the shelf life of coffee beans .

OPP bag is a kind of plastic bag made of polypropylene as raw material, with the following characteristics:

Good sealing: The tightness of the new OPP film is more than twice that of its traditional film, which helps to moisturize and preserve the product2.

Strong anti-counterfeiting: the use of synthetic technology and special printing technology to improve the difficulty of counterfeiting 2.

Environmental protection: The raw materials used in OPP bags are degradable materials, which meet international environmental standards 2.

OPP bags are widely used in jewelry, jade, stationery, toys, tableware, kitchen utensils, clothing and other fields, especially in the outer packaging of commodity sales, which can protect products and improve beauty